Sizing the Gates: Ideal Valve Diameter in 2-Valve Engines

In a 2-valve engine, the intake and exhaust valves are the sole gateways for airflow. Their diameter is a critical balancing act: large enough to allow maximum airflow for high-RPM power, yet small enough to maintain high air velocity for low-RPM torque and throttle response. Finding the ideal diameter is fundamental to defining the engine's entire performance character.

The Mathematical Approach

Empirical formulas, derived from decades of engine building, provide a powerful starting point for determining valve size based on the engine's capacity.

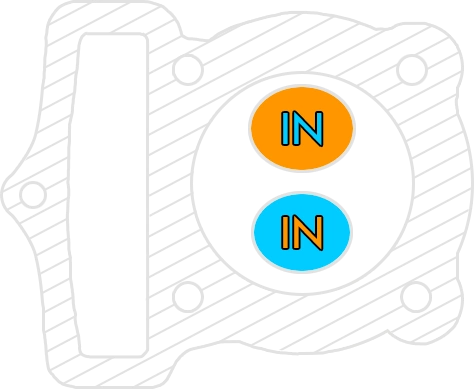

Intake Valve Diameter (Ø)

The intake valve is the primary focus, as filling the cylinder efficiently is the biggest challenge. Its ideal size is closely related to the volume it needs to serve.

Exhaust Valve Diameter (Ø)

The exhaust valve is typically sized as a percentage of the intake valve. This ratio is a critical tuning parameter.

Why is the Exhaust Valve Smaller?

The intake stroke relies on atmospheric pressure to push air in, while the exhaust stroke actively pushes hot, high-pressure gases out. Because exhaust gases exit more easily, the exhaust valve doesn't need to be as large. The ideal ratio (typically 75-90%) depends on the engine's application.

High Ratio (e.g., 85-90%)

Favored in naturally aspirated race engines. A larger exhaust valve promotes better "scavenging," helping to pull out all spent gases and draw in the fresh intake charge more effectively during overlap.

Lower Ratio (e.g., 75-80%)

Often used in turbocharged engines. The turbo creates significant backpressure, so a smaller exhaust valve can help maintain gas velocity towards the turbine. It's also common in street engines focused on low-end torque.