The Quest for Ideal Lift: Unlocking Your Engine's Airflow Potential

In engine tuning, "ideal valve lift" represents the theoretical sweet spot where the valve opens just enough to maximize airflow without introducing turbulence or inefficiencies. It's not about the maximum possible lift, but the most effective lift for a given valve size, forming the scientific baseline for high-performance camshaft design.

The Science of Curtain Area

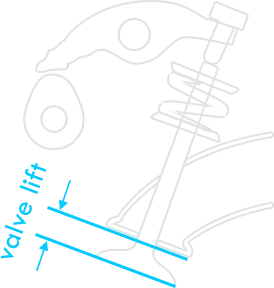

Air doesn't just flow through the valve opening; it flows around the valve head. The effective opening is a cylindrical shape called the "curtain area."

- The Point of Diminishing Returns

- Theory states that once the curtain area equals the valve's physical area, the valve itself is no longer the primary restriction—the port is. This happens when lift is 25% of the valve's diameter.

- The Magic Number: L/D Ratio

- This relationship is expressed as the Lift-to-Diameter (L/D) ratio. A theoretical ideal L/D ratio is 0.25, which serves as the fundamental starting point for all camshaft and cylinder head design.

From Theory to Reality: Famous Constants

While 0.25 is the theoretical ideal, real-world flow benches show that ports have inefficiencies. Famous tuners have derived constants to account for this.

A. Graham Bell's Constant (3.57)

A widely respected figure, Bell's empirical data suggests a slightly higher lift is needed to achieve the "effective" curtain area in most practical applications, compensating for minor flow restrictions near the valve seat.

Superflow Bench Constant (3.125)

Derived from extensive testing on industry-standard flow benches like the Superflow SF-110, this constant suggests an even higher lift is often required to maximize flow, accounting for more significant real-world port and chamber inefficiencies.

*NB: A smaller constant demands a higher theoretical lift value to compensate for greater assumed flow restrictions.

Beyond the Calculator: What Really Matters

Cylinder Head & Port Design

A highly efficient, CNC-ported head might achieve peak flow close to the 0.25 L/D ratio. A stock, restrictive head will require more lift to force the same amount of air through.

Application & RPM Range

A high-RPM race engine needs massive airflow and can benefit from lifting well beyond the ideal point. A street engine needs low-RPM velocity for torque and drivability, where excessive lift can be detrimental.