Unlocking Airflow: The Critical Role of Valve Lift

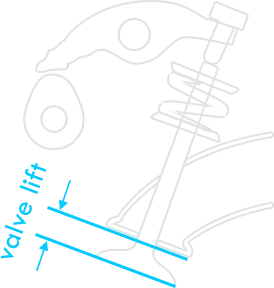

Valve lift is the maximum distance a valve opens from its seated position in the cylinder head. This single measurement is one of the most crucial factors in engine performance, as it directly dictates the primary gateway for the air/fuel mixture to enter the cylinder. More lift generally means more airflow, and more airflow means more power.

How Valve Lift is Created

The fundamental calculation is a simple multiplication:

- Lobe Lift

- This is the actual physical height of the camshaft's lobe—the bump that initiates the entire process. A more aggressive cam profile will have a physically taller lobe.

- Rocker Arm Ratio

- The rocker arm acts as a lever, multiplying the initial movement from the camshaft. A common ratio is 1.5:1, meaning the valve will open 1.5 times higher than the lobe's physical lift.

High Lift vs. Low Lift: A Tale of Two Engines

High Lift Profile

Ideal for high-RPM race engines. It allows a massive volume of air to enter the cylinder, maximizing peak horsepower. However, this often sacrifices low-RPM air velocity, leading to poor torque and drivability on the street.

Low Lift Profile

Perfect for daily drivers and street performance. By keeping air velocity high at lower RPMs, it enhances throttle response and low-end torque. This creates a responsive, efficient, and enjoyable driving experience for everyday use.

The Limiting Factors: Why More Isn't Always Better

- 1. Piston-to-Valve Clearance

- The most critical limitation. If the valve opens too far, it can physically collide with the piston as it reaches the top of its stroke, causing catastrophic engine failure.

- 2. Valve Spring Control & Float

- Valve springs must be strong enough to close the valve instantly. Weak springs can't keep up at high RPM, causing "valve float," where the valve doesn't fully seat, leading to a loss of compression and power.

- 3. Cylinder Head Flow Capacity

- There's no point in having high lift if the cylinder head ports are restrictive. The entire system—port, valve seat, and chamber—must be designed to take advantage of the increased airflow potential.